BIO-SEA Technology

Mechanical filtration, UV disinfection and automated monitor control to give ship operators compliance confidence.

Two proven and trusted technologies

BIO-SEA offers 2 proven and reliable technologies to manage non-indigenous marine organisms in ships’ ballast tanks: mechanical filtration and UV disinfection. To deliver maximum treatment capability. This two-pronged approach gives ship operators compliance confidence.

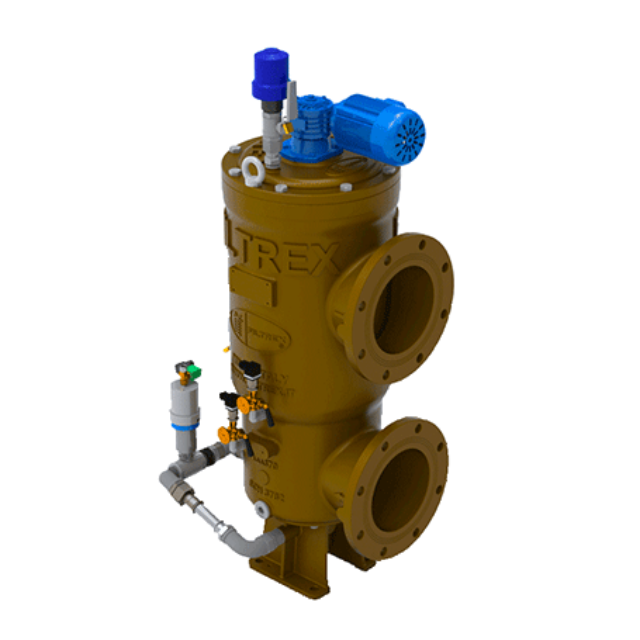

Mechanical filtration

Ballast water goes through a 20μm stainless steel screen filter to remove larger organisms from the ballast water.

Filters are back flushed and cleaned automatically to ensure all organic matter has been removed, filters are clean, and there are no fluctuations in treatment performance.

Included is an additional suction pump to facilitate enhanced cleaning even if the normal service pressure is low.

Successful filtration is vital to the performance efficiency of the subsequent UV disinfection process.

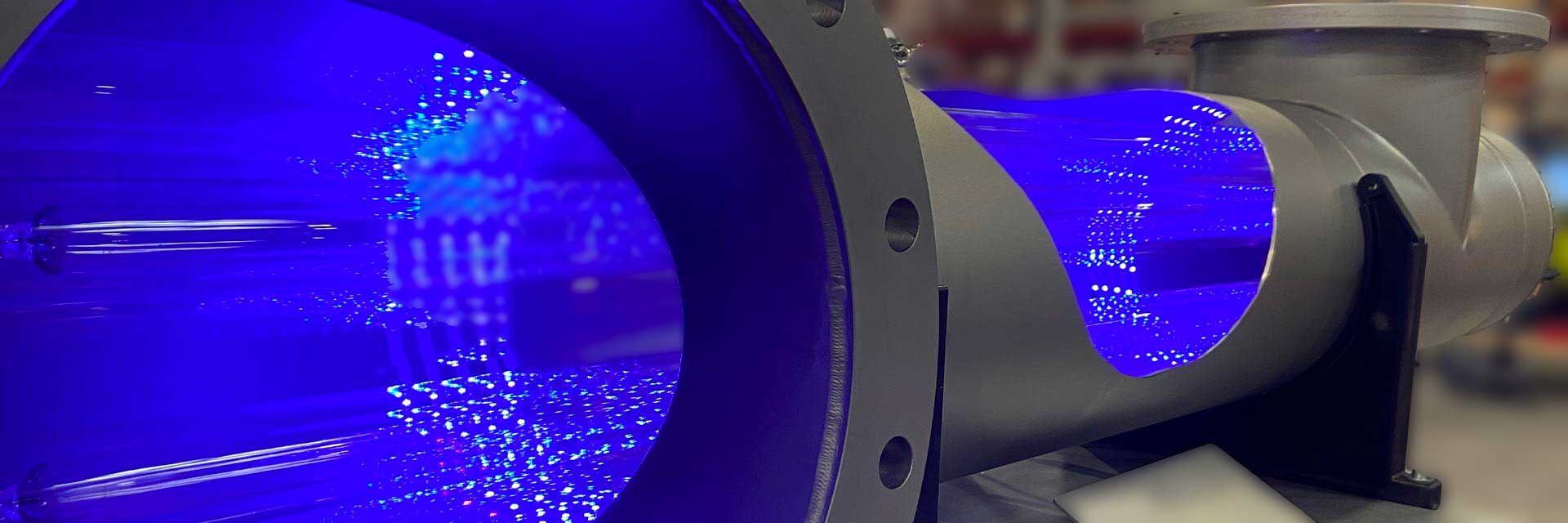

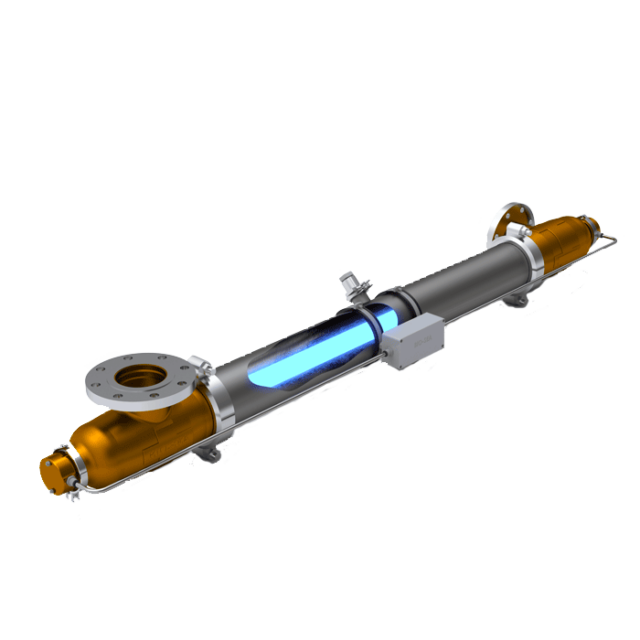

UV disinfection

All BIO-SEA reactors are made from titanium and contain the most advanced UV-C lamps emitting high intensity rays of UV to destroy organisms, viruses, bacteria, algae, yeasts, and mould.

BIO-SEA by BIO-UV Group’s UV-C technology penetrates the microorganisms’ DNA to disrupt and destroy cells, preventing reproduction.

Dosing is completely chemical free controlled and automatic to keep operational costs to minimum.

Automation & Control

From initial filtration, through to disinfection and system cleaning, all BIO-SEA ballasting operations are carried out automatically to save operators time and money.

State-of-the-art sensors and programmable logic controllers (PLC) help deliver an easy-to-use control and monitoring interface.

Each BIO-SEA system features:

- Automatic and/or manual operation for ballasting, de-ballasting, and cleaning

- Automatic dosage/UV intensity

- Automatic back flushing and filter cleaning

- User-friendly touch screens

- Bus communication for remote control and integration to vessel automation system and command control

- Operator and administrator modes

- Recording of operations, alarms, and measured UV intensity